Frequently Asked Questions

Got a question?

We encourage you to browse our FAQs before making your Resiscape purchase.

Can't see your question?

Contact Us-

Our Resiscape resin bound aggregates are available to purchase through our extensive network of distributors and stockists. To find your nearest stockist, please contact us.

-

Each 4m2 Kit contains:

- 3 x 25kg Bags of 2-5mm Aggregate

- 1 x 12.5kg Bag of 1-3mm Aggregate*

- 1 x 6.25kg Bag of C50 Sand

- 1 x Tub Part A Resin

- 1 x Tub Part B Hardener

Please note: All weights and measurements are nominal with a tolerance of +/- 5%.

*The Dorset Gold aggregate is 1-2mm.

-

A solid sub base is required for the Resiscape system to be installed, this could be existing concrete or tarmac. If there are any cracks present in the existing surface, we would advise laying a new sub base before installation.

-

You can view our full, step-by-step installation guide here.

-

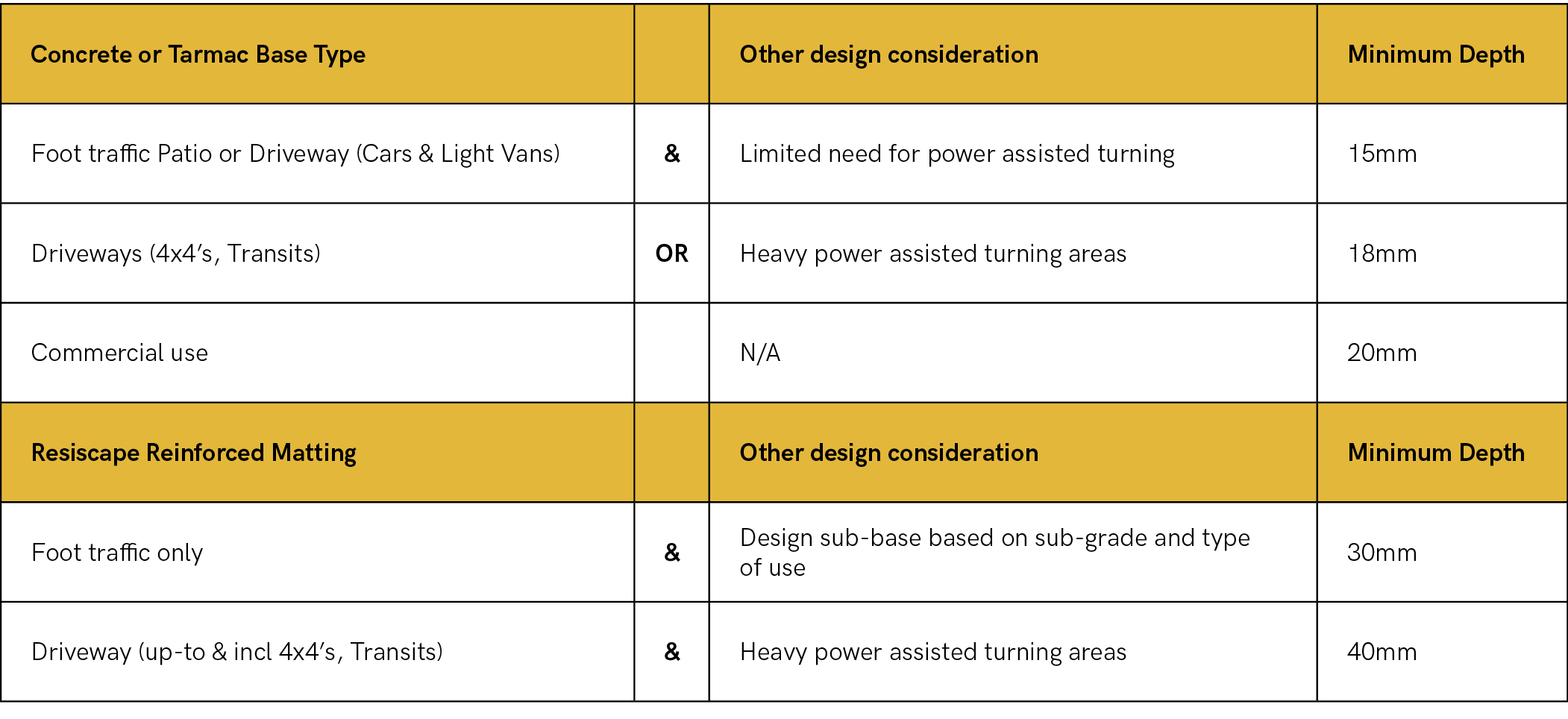

If the resin mix has been laid at a depth of 15mm, the surface will take domestic traffic, cars, vans etc. For heavier trafficked areas we recommend a thicker resin mix is applied. Use the below guide to ensure your Resiscape thickness is adequate for its intended application.

-

We recommend that you always slightly over order when first ordering your materials, to ensure you can complete the job on site once started.

-

On average the resin will take 20-30 minutes to set. In the warmer months, setting times can be as low as 10-15 minutes.

-

Each Resiscape kit will cover a maximum of 4m2 at 15mm depth. This is based on laying on a smooth surface and does not take into account surface texture or wastage.We recommend that an extra 10% of materials are ordered as the system is hand trowelled and provisions need to be taken for undulations in the sub base.

-

Once the driveway has been laid, we recommend that 24 hours is left for the driveway to fully cure. A longer curing time can be expected in cooler temperatures. Ensure the surface isn’t soft or tacky before walking on the area.

-

The conditions need to be fair when the system is installed, the temperature should be between 5 and 25 degrees celsius and the stone and surface temperature should be at least 3 degrees above dew point. It is important that the surface is dry when the system is installed and doesn’t come into contact with water when curing.

-

The product should not be laid if there is any rainfall, as this could result in ‘foaming’, resulting in a failed surface.